Coventry Chaser

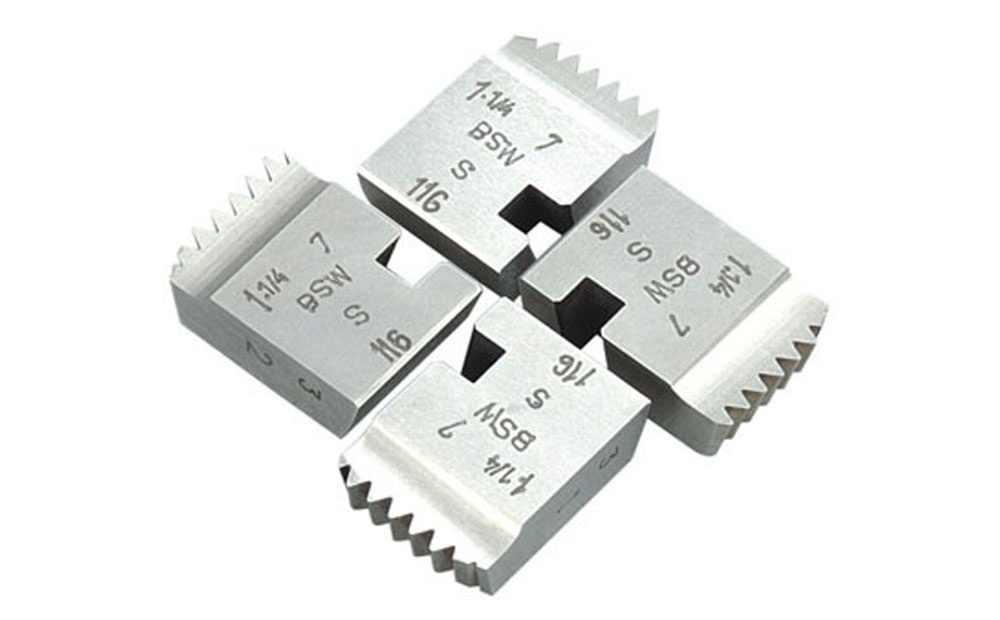

Marking on dies : Each die is marked. There is no gauge number for this type of die because only the throat is reground face remains intact on these straight-cut type of dies.

Throats : Phoenix Tools dies are supplied for these die heads with four standard throat angles 15°, 20°, 33° and 45° and their Z cations are. The longer the throat the better the distribution of chips. This means easier cutting, better finish on the and longer die life.

On Acme, Worm, Modified Square and similar thread forms, a tow thread throat is approximately 15° a one -thread throat approximately 33°. As the cutting is all done by the throat and first full tooth it is important that the throat is right for the work.

FITTING the Die into the Diehead : Geometric die heads have the die slots numbered 1,2,3, or 4 and the dies are marked in similar sequence. It is important that each die is inserted in the slot with the same number. For die heads which have slots which are not numbered, the dies should be fitted into the die head in numerical order, in a clockwise direction looking at the front of the die head but it does not matter which slot of the die head is taken to start. This applies whether the dies are for right hand or left hand threading.

Adjusting Dies to Size : If a sample screw is available adjust the dies to this part . If not, use as a setting gauge a piece of bar stock turned to the minor (root) diameter of the thread to be cut. Care should be taken not to force the chasers into the setting gauge.

| Material | Rake Angle | Material | Rake Angle |

|---|---|---|---|

| Aluminium | 10-25° | Gunmetal | 0-5 |

| Bakelized Paper | 45 neg. | Iron. Cast | 15° |

| Barss bar | 10-22° | Malleable | 18-22° |

| Cast | 5 Neg. 0° | Wrought | 5-22° |

| Bronze bar | 10-22° | Monel metal | 25-30 |

| Cast | 0-10° | Steel Cast | 12° |

| Manganese | 0-10° | Free Cutting | 15-30° |

| Phosphor | 0-10° | High tensile | 25° |

| Copper | 28° | Mild | 18-22° |

| Duralumin | 25-30° | Nickel | 18-25° |

| Ebonite | 0-10 neg° | Stainless | 25° |

| Erinoid | 0° | Vulcanite | 0° |