A WORD ABOUT PHOENIX TOOL BITS

RAW MATERIAL : Phoenix Tool Bits are made from finest grades of imported steel. These steel are further tested in our well equipped laboratory for grain size, chemical composition other variables and defects before further processing. This includes a whole battery of tests, from spectroscopic examination for chemical composition to microscopic tests for carbide distribution . It is made sure that raw materials used meet with our requirements.

PRECISE HEAT TREATMENT : Heat Treatment is what transforms a soft, pliable piece of steel into hard, tough and wear resistant Tool Bit . Hence other things remaining same it is the Heat Treatment that makes a Tool-Bit very much different from other Tool-Bit.This is the factor where there is no chance for compromise on quality. We have therefore opted for furnace manufactured under German licence to ensure precise Automatic temperature control and of course very close process control. Even then each batch is carefully tested for microstructure and each tool for hardness in well equipped laboratory and quality control department . After well controlled further processing what we have is Phoenix tool-bit to give you the best in every desired quality.

DESIRABLE PROPERTIES OF GOOD TOOL BITS :

HOT HARDNESS : A tool fails or performs poor at high speed of cutting if it has low hot hardness because high speed involves high temperature at the cutting edge which tends to soften the edge.

WEAR RESISTANCE : A tool may have same hardness or even lower but can stand the wear during cutting better just as valconised rubber compared to wood.

TOUGHNESS : This is most desirous property for any type of tool as capacity of tool to withstand vibrations. and shock loads depends on its toughness. This may also be called "Lack of Brittleness... This allows tool to slightly "bend" rather than "break" under shock or heavy load.

PHOENIX TOOL BIT INCORPORATES ALL THE ABOVE IN APPROPRIATE DEGREES.

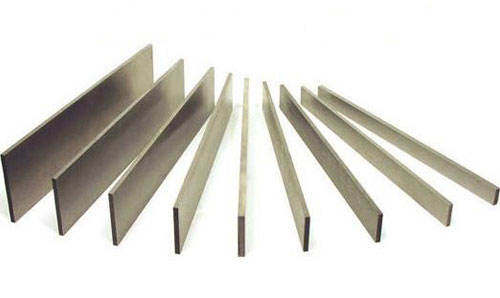

PHOENIX TOOL BIT ARE AVAILABLE IN FOLLOWING GRADES & RANGES

SINGLE S : Phoenix single S Tool Bits are made from M-2 High Speed Steel. This time proved tungsten molybdenum material has excellent toughness and wear-resistance. It is an economical grade for general shop purposes. It is best suited for applications involving interrupted cuts and roughing operation where strength is a pre-requisite.

DOUBLE SS : Phoenix double SS tool bits have a high degree of hot hardness and wear-resistance. Made from 8% cobalt bearing M-42 steel, these offer top efficiency on difficult to machine alloys and high strength steels.

TREBLE SSS : Phoenix Treble SSS tool bits have exceptional wear resistance property. Made of 10% cobalt bearing T-42 steel. these also have a high hot hardness, edge holding ability and ample toughness for all types of cutting tool applications. particularly at high temperatures and high speeds . They are especially adopted for roughing or finishing operations where maximum tool life is required for large batch automatic lathe work and all types of lathe and boring operations.

HOW TO GET BEST OUT OF PHOENIX TOOL BITS :

CORRECT GRINDING : The heat generated while grinding the cutting edges reduces the hardness at the cutting edges, thereby lowering the cutting efficiency of a sharpened tool. Therefore, when grinding tool bits : * Use a soft wheel. appropriately dressed.* Apply Light pressure & constantly rotate the Tool Bit surface to avoid discoloration or burning of the cutting edge. * Avoid sudden change of temperature DO NOT dip the hot Tool in cold water (otherwise the Tool will develop surface cracks, which reduce the Tool efficiency & life) * Hand stoning of the finish ground faces lengthens life between regrinds & enhances surface finish achieved with finishing cuts.

CORRECT FORM : To get high cutting efficiency it is vital that correct Tool geometry (Profile) is maintained when regrinding the Tool. Correct grinding of various angles of a tool can greatly improve the Tool bit's performance. Please refer to the Phoenix chart for details of correct angles for different materials.